What We Do

Manufacturer of Wire and Bars for the Aerospace Industry

Brown Europe is committed to be the highest quality manufacturer of Alloy, Stainless, Nickel and high-temperature alloy wire and bar products in the industry.

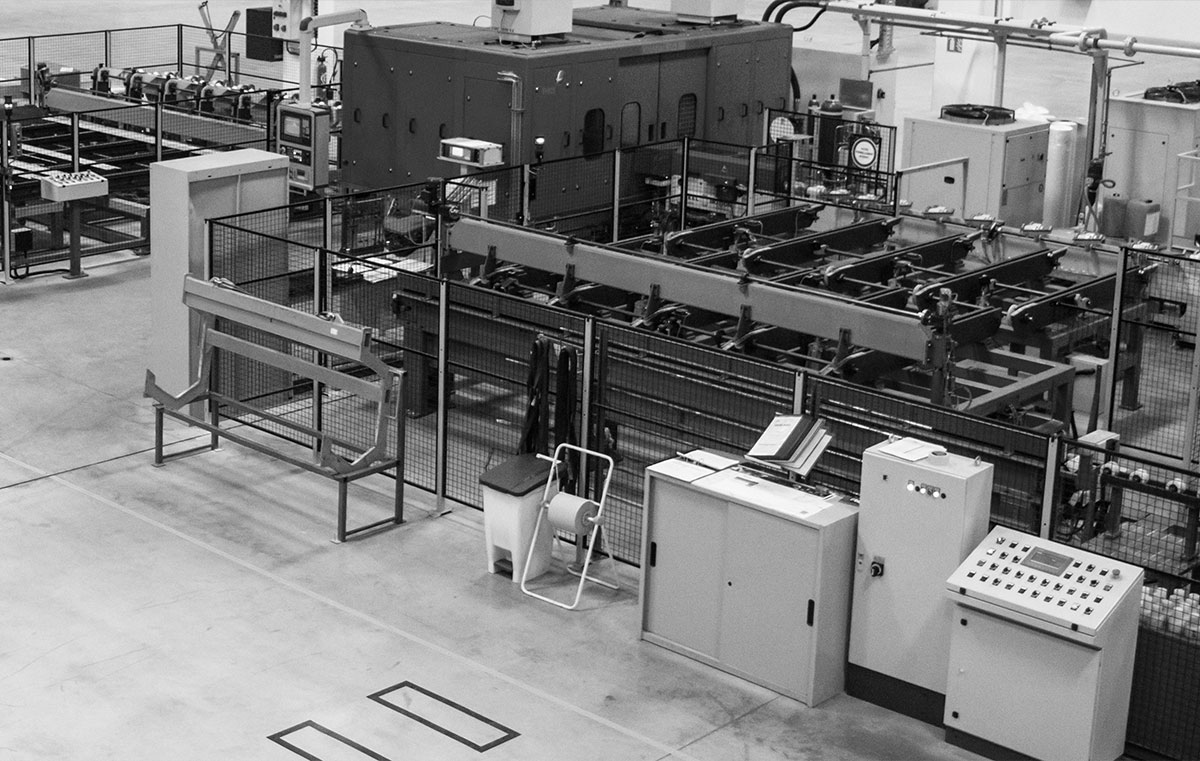

Drawing

5000 M2 (53,820 SqFt) of wire drawing facility to produce customized sizes with minimal set-up time for size changes and delivering industry-leading surface quality for seamless cold heading wire.

Surface Preparation

A combination of physical and chemical processing for removal of material, ensuring elimination of IGA lines and final clean on product’s surface.

Surface coating

From strand copper plating to Molykote, including Miraflex and, or Soap coating, Brown Europe can meet all our customers’ specific requirements while controlling thickness and maintaining full production control.

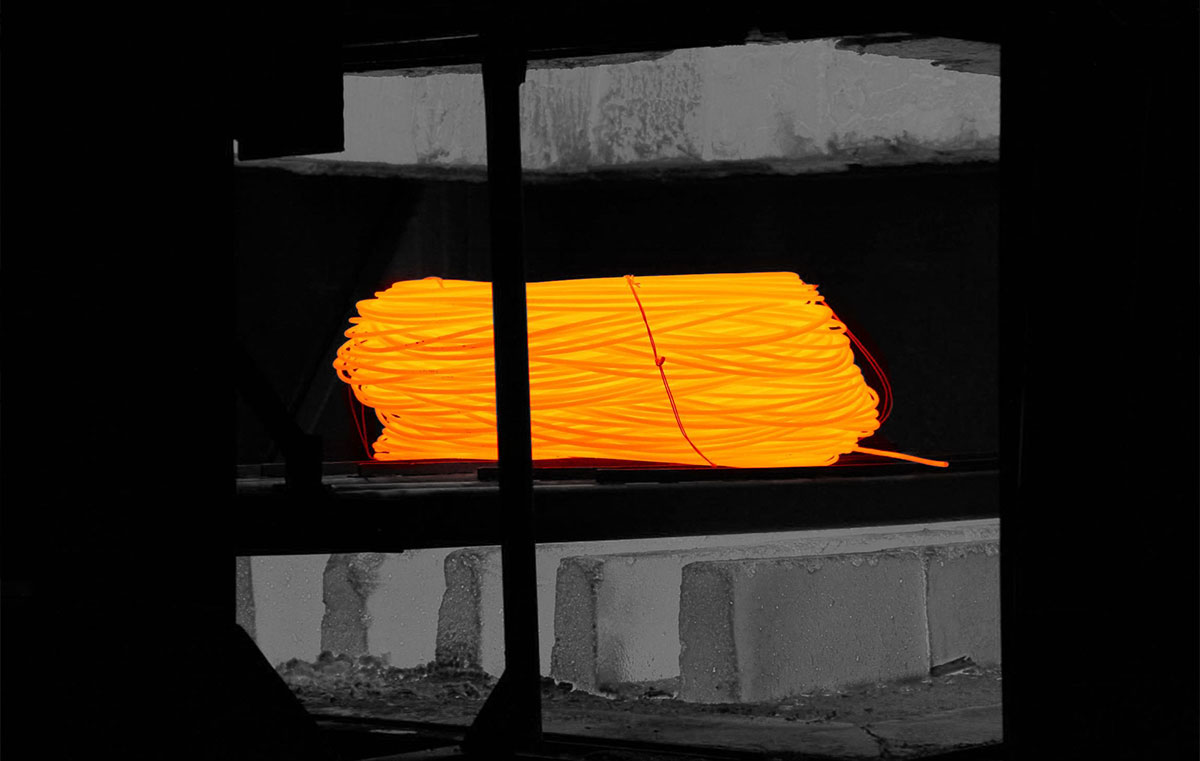

Thermal Treatment (heat treating and annealing)

Advanced furnace capabilities contribute to an outstanding operating efficiency, enhanced production scheduling, increased capacity and improved delivery reliability through in-house heat treat capability.

Bar Straightening & Grinding

Capability to manufacture bars on-site from the high-quality wire, free from surface defects and maximizing yields through efficient automated production lines.

Testing

All orders are tested in Brown Europe’s lab for required mechanical properties with multiple checks throughout the manufacturing process ensure conformity without increasing production time.